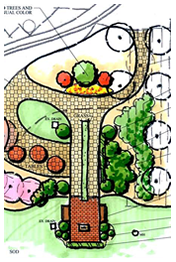

A&C develops hardscape, landscape, and site construction services for distinctive clientele with difficult delivery, schedule and site constraints.

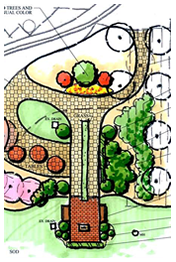

A&C develops hardscape, landscape, and site construction services for distinctive clientele with difficult delivery, schedule and site constraints.